Product Description

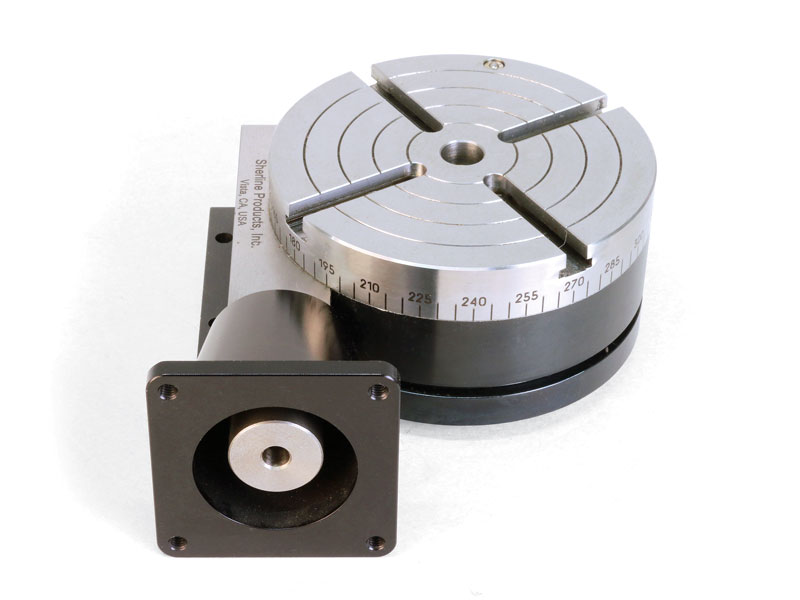

Sherline has taken its P/N 3700-OP manual 4″ rotary table and applied a stepper motor mount with dampened coupling in place of the handwheel. The mount accepts a NEMA #23 frame size stepper motor for CNC control. This allows the table to be used as a 4th axis with CNC systems that have the capability to drive a rotary axis.

The reverse rotary table is perfect for using on the tilting angle table (P/N 3750). The reverse mount allows access to the handwheel from the front of the machine (see photo below). If you used a standard rotary table in the previously described set-up the handwheel would be mounted facing the backside of the X-axis.

NOTE: We are stating the following weight limits for our rotary tables for continual use.

- Horizontal orientation—50 lbs.

- Vertical orientation—30 lbs.

- Vertical rotational torque—6 foot/lbs. (meaning it can lift a 6 lb. weight when suspended 12″ away from the center of the rotary table)

The rotary tables can hold more weight when they are not under a continuous load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

NOTE: CNC-ready machines cannot be operated manually until stepper motors are installed.

- 2 35580 Hold-down clamps

- 4 30561 10-32 T-nuts

- 2 40330 SHC Screw, 10-32 X 5/8″

- 2 40510 SHC Screw, 10-32 X 3/8″

- 1 37090 Chuck Adapter

If you would like to convert your current rotary table to the reverse set-up you can send it back to Sherline and we can make the change for an $104.25 charge (includes parts and labor). Just call one of our customer service representatives to set up a work order.

NOTE: Because components of the table are ground as a set during production, the P/N 3700-OP rotary table cannot be upgraded to the P/N 3700-CNC-OP version later on. A new rotary table with stepper motor worm housing must be purchased.

For in-depth details about the Sherline CNC-Ready 4″ Rotary Table CLICK HERE.